Brushless DC motor applications: examples that demonstrate their features

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

1 Feb. 2021

DC motors, with or without brushes, are used in a wide variety of applications, featuring a high level of starting torque and an ability to rotate at high speed. Brushless DC motors are quieter than brushed motors, with a longer life and lower maintenance requirements.

This page looks at where brushless DC motors are used and describes their applications in various fields.

Features and advantages of brushless DC motors

Let’s start with a simple explanation of what DC motors are. DC motors are electric motors that are powered by direct current. Features include rotation at high speed and the ability to deliver high starting torque. The motor’s speed and torque are controlled by means of the drive voltage.

DC motors can be broadly divided into brushed DC motors and brushless DC motors, depending on whether they use brushes as an electrode. The shorter life of brushed DC motors is because they are equipped with brushes and a commutator, which are both consumable parts. Brushless DC motors on the other hand, as their name suggests, do not have brushes. Instead, they are driven by turning the transistor in the drive circuit on and off based on the signal from a magnetic sensor inside the motor.

Because brushless DC motors don’t use consumable brushes and have their current flow switched electronically, they feature low maintenance and long life. Another attraction is that they run more quietly than brushed motors.

This low level of motor noise means they are frequently used to make household electronic devices and other such equipment operate more quietly.

Applications in home appliances and commercial electrical products

While daily life provides few opportunities to see brushless DC motors in action, they are frequently found inside commonly used home appliances. Air conditioners and refrigerators are two examples. Such appliances use fans to deliver chilled or warm air, and brushless DC motors are used to drive these fans.

Likewise, the motors are increasingly being used in electric fans. The blades of household fans rotate at very high speed and tend to make motor noise. Therefore brushless DC motors are widely adopted in models that feature quiet operation and fine-grained adjustment of fan power.

Another application for the motors is in commercial electrical products. Examples include feeding paper in laser printers, controlling the propellers and gimbal in drones, and turning of screwdrivers or saws in power tools. In other words, brushless DC motors are extremely versatile.

Brushless DC motor case studies

More than just a change of motor. Other challenges overcome to achieve further reductions in size.

Proposal kickstarts new product development overcoming hidden obstacles. Reduced development costs together with enhanced product energy efficiency.

Applications in precision devices

Brushless DC motors are widely used in precision devices. Major examples include the hard drives used in PCs and DVD players, other PC drives, and Blu-Ray recorders. Disk rotation is a vital function for these devices. Brushless DC motors are used in the spindles that rotate the disks.

Most everyday applications of this type demand a long product life. With their long life and low maintenance requirements, brushless DC motors have carved out an essential niche for themselves in the precision device sector.

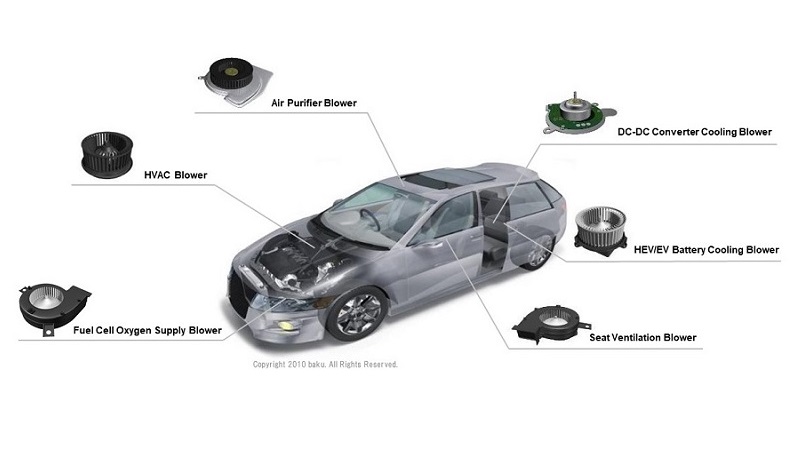

Applications in automotive industry

As already noted, the use of brushless DC motors has been growing in recent years. Moreover, it is in the automotive industry that this growth has been most pronounced. A wide range of electronic devices are involved in driving a car. Among the main applications are:

- Electric power steering motors

- Electric oil distribution motors

- Headlamp leveling motors

- Electric parking brake motors

- Electric active stabilizer motors

- Motors for automatic hatch opening and closing

- Door lock motors

- Motors for door opening and closing

- Seat cooling fan motors

Vehicles pose a risk not only to their driver and passengers, but also to pedestrians and other road users. With their long life and low maintenance requirements, brushless DC motors are widely used in applications that are aimed at keeping this risk to an absolute minimum. Meanwhile, the quiet operation of these motors also helps to provide a more comfortable driving experience.

Identifying applications where brushless DC motor features can be put to good use

Because they do not use brushes, brushless DC motors benefit from long life, ease of maintenance, and quiet operation. Taking advantage of these features, they are used in many different aspects of our lives.

These range from electronic devices commonly used as home appliances to electrical products for industrial applications. Their uses in these products are diverse. Over recent years, they have also increasingly come to be used in the automotive industry where the demand is for comfort and safety. Perhaps you should take a fresh look at how brushless DC motors can be put to use in your own field.

Overcoming your problems with brushless DC motors

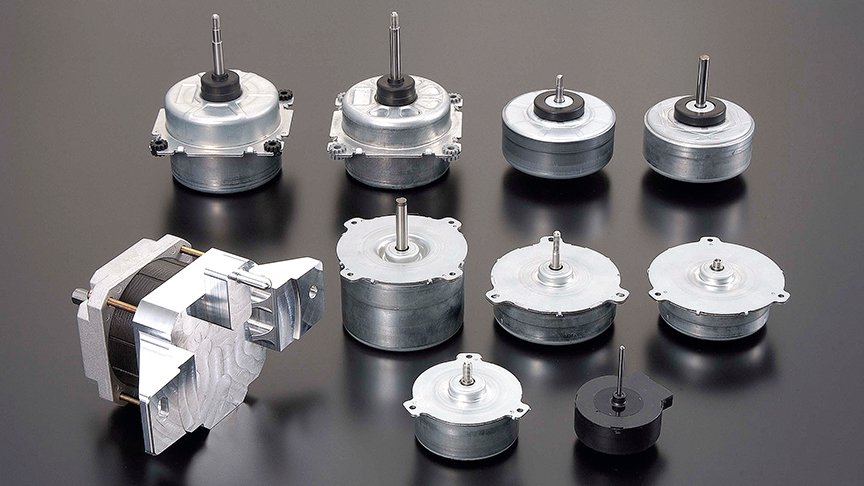

ASPINA supplies not only standalone brushless DC motors, but also system products that incorporate drive and control systems as well as mechanical design. These are backed by comprehensive support that extends from prototyping to commercial production and after-sales service.

ASPINA can offer solutions that are tailored to suit the functions and performance demanded by a diverse range of industries, applications, and customer products, as well as your particular production arrangements.

ASPINA supports not only customers who already know their requirements or specifications, but also those who are facing problems at early stages of development. Do you struggle with the following concerns?

Motor selection

- Don't have detailed specifications or design drawings yet, but need advice on motors?

- Don't have anyone in-house with expertise in motors and can't identify what sort of motor will work best for your new product?

Motor and associated component development

- Want to focus your resources on core technology, and outsource drive systems and motor development?

- Want to save the time and effort of redesigning existing mechanical components when replacing your motor?

Unique requirement

- Need a custom motor for your product, but been declined from your usual vendor?

- Can't find a motor that gives you the control you require, and about to give up hope?

Seeking answers to these problems? Contact ASPINA, we’re here to help.

List of the same series columns

- Applications for blower motor

- What is a blower motor?

- Advantages of brushless DC motors over brushed DC motors

- Features and applications of DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- Different types of DC motor and their respective features

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- Difference between brushed motor and brushless motor

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- How do brushless DC motors work? The need for a drive circuit explained

- Do brushless DC motors require a drive circuit? – Controlling brushless DC motors

- What is a brushless DC motor?

- How do brushed DC motors work? The need for regular maintenance explained

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

- What is a DC motor? - features and mechanisms

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others