Advantages of brushless DC motors over brushed DC motors

-

Automation

-

Health & wellness

-

Life environment

-

Automotive

10 Feb. 2022

DC motors can be generally divided into brushed and brushless motors, with brushless motors outperforming their brushed counterparts in many different areas. This page goes into detail about the advantages that brushless DC motors have over brushed DC motors, and how the two types of motors differ from one another.

Differences between brushed and brushless DC motors

The different structural configurations of brushed and brushless DC motors affect the flexibility of motor shape and dimension design. Other differences that are closely related to this are the available choice of motor characteristics, levels of electrical and mechanical noise, and thermal characteristics. Similarly, not having parts that wear against one another means that brushless DC motors can also achieve long life and stable rotational performance.

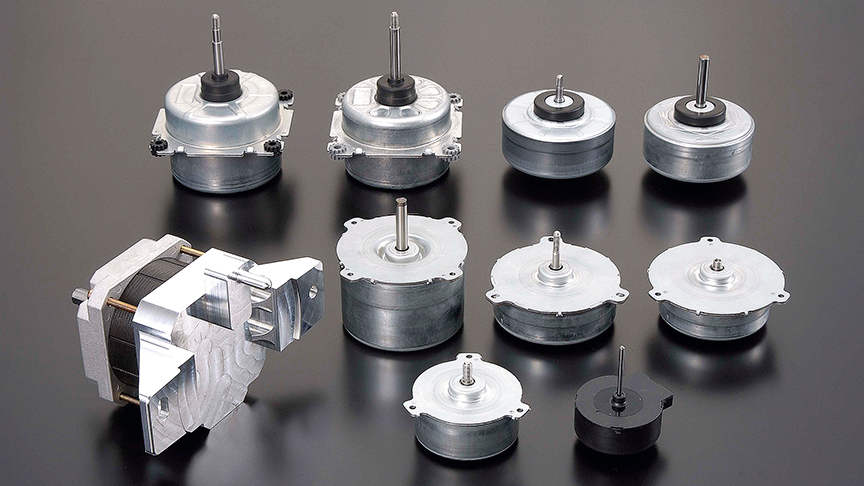

Design flexibility due to different motor structure

Whereas brushed DC motors generally have the shape of an elongated cylinder, the flattened shape and larger diameters possible with brushless DC motors provide the additional option of disc-shaped motors. The motor body can be made thinner, which facilitates the design of slimmer and more space-efficient end products.

Wider choice of motor characteristics

As the drive and control circuits for a brushless DC motor can be designed to suit the required performance, a wider range of characteristics can be achieved than with brushed DC motors. This offers a much wider range of speed and torque control than is possible with brushed DC motors.

Electrical and mechanical noise

Brushed DC motors are a source of electrical noise caused by the sparks generated in the electrical contact between brush and commutator. Brushless DC motors, on the other hand, do not have brushes and commutator rubbing against one another in electrical and mechanical contact and therefore do not produce electrical noise due to sparking nor mechanical noise due to the inevitable friction. This makes it possible to minimize noise and vibration in the end product and keep radio frequency interference with other electronic devices to a very low level.

Thermal characteristics

Brushed and brushless DC motors are structurally different, and these differences influence their respective thermal characteristics. As the basic design of brushed DC motors involves a rotating coil (armature) that both generates heat and is enclosed in a magnet and case, their thermal characteristics are not always ideal.

Brushless DC motors, on the other hand, offer a choice of two configurations depending on whether the rotor is located inside or outside the stator, which is where the heat is generated. In both configurations, the surface area exposed to air is greater than that of a brushed DC motor and this accounts for the superior thermal characteristics of brushless DC motors.

Brushless DC motors are used in home appliances, in commercial and industrial equipment

Over recent years, the excellent efficiency and low noise of brushless DC motors have led to the expansion of their use into applications such as electrical products and precision machinery.

Refrigerators, washing machines, air conditioners, fans, and domestic water heaters are just some of the home appliances that use brushless DC motors. Commercial uses include office, industrial, and medical equipment.

High-speed disc rotation is an essential requirement in various mechatronic devices such as the HDDs, optical drives, and Blu-ray recorders used in familiar products like PCs and DVD players. The component used to control this rotation is a brushless DC motor.

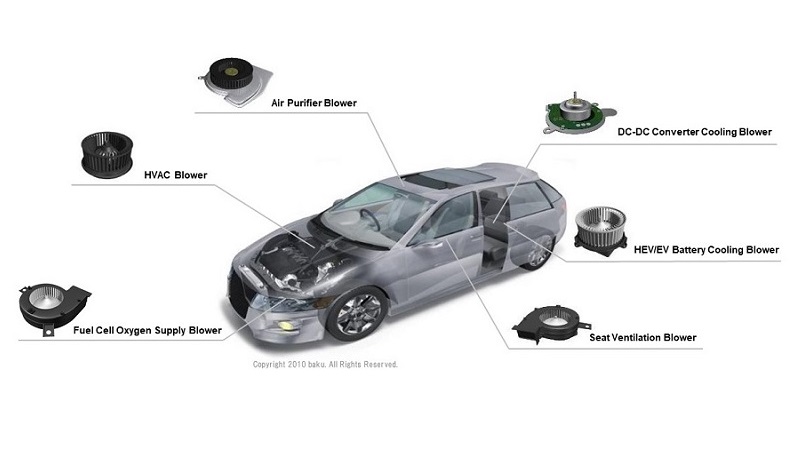

Beyond home appliances and precision equipment, a wide range of systems that incorporate brushless DC motors have also been developed in the automotive industry.

- DC motors for electric power steering

- Fan motors for seat air conditioning

- Fan motors for HVAC (the primary car air conditioning system)

While these are only some of the parts that utilize DC motors, brushless DC motors have become a vital component for enhanced comfort and safety performance.

“Smaller, lighter, quieter”: The threefold benefits of brushless DC motors

The compact size, light weight, and quiet operation of brushless DC motors provide opportunities for their use in many different applications. By taking advantage of these threefold benefits, brushless DC motors can be used to create products with long-lasting performance in areas as diverse as home appliances, precision equipment, and automotive parts.

Advantages of brushless DC motors (summary)

This page has explained the differences between brushed and brushless DC motors, and the ways in which brushless motors are better.

The superiority of brushless DC motors comes from the following features:

- Design flexibility due to different motor structure

- Wider choice of motor characteristics

- Significant advantages in electrical and mechanical noise

- Thermal characteristics

Brushless DC motors are now used across all sorts of different areas, from home appliances to automotive parts. For those of you uncertain about the best choice of brushless DC motor, we hope this page will prove to be useful and that you will chose an ASPINA brushless DC motor.

List of the same series columns

- Applications for blower motor

- What is a blower motor?

- Features and applications of DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- Different types of DC motor and their respective features

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- Difference between brushed motor and brushless motor

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- How do brushless DC motors work? The need for a drive circuit explained

- Do brushless DC motors require a drive circuit? – Controlling brushless DC motors

- What is a brushless DC motor?

- How do brushed DC motors work? The need for regular maintenance explained

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

- What is a DC motor? - features and mechanisms

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others