Different types of DC motor and their respective features

-

Automation

-

Health & wellness

-

Life environment

-

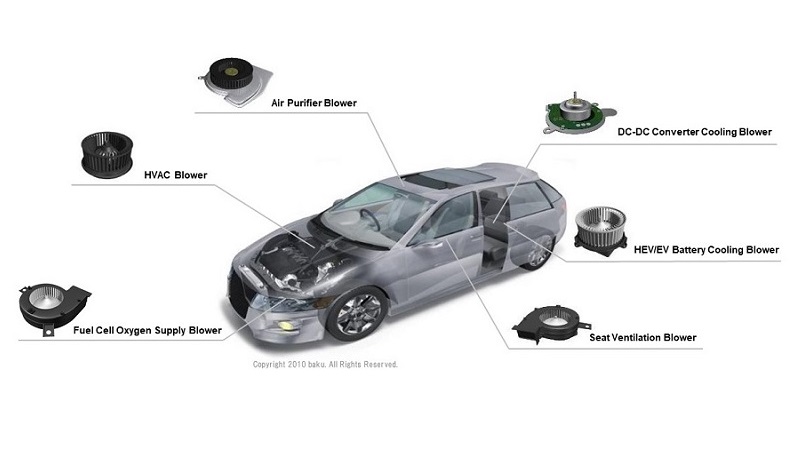

Automotive

7 Feb. 2022

“Electric motor” is the general term for a machine that converts electrical energy into mechanical energy. This type of motor is widely used in products such as home appliances, robots, and pumps.Use of electric motors has also grown considerably in the automotive field over recent years, not least of which is their use in electric vehicles.

Electric motors come in many different varieties, one of which is the DC motor, where DC is an abbreviation of “direct current”. These DC motors are used in a wide range of familiar products. They can be further divided into brushed and brushless motors.

Brushed DC motors

DC motors are either brushed or brushless.Brushed motors are driven by connection to a DC power supply. As brushed motors maintain physical contact between the brushes and commutator as they rotate, both of these parts are subject to wear. Moreover, brushed motors also generate sparks when making and breaking the electrical contact between brush and commutator. This in turn generates electrical noise. Mechanical noise is also produced by the two parts rubbing against one another.

Brushed DC motors can also be further divided into permanent magnet motors and electromagnet motors, each of which has different characteristics.

Permanent magnet brushed DC motors

A permanent magnet is a material that is able to retain its magnetism for a comparatively long period of time without the need for an external magnetic field or electrical current to be supplied. Brushed DC motors in which the stator contains permanent magnets are called permanent magnet brushed DC motors.

Globally, this type is widely used in applications such as auxiliary automotive motors or in model cars or boats. They can also be further subdivided based on the design of the rotor, into slotted, slotless and coreless motors.

Electromagnet brushed DC motors

An electromagnet is made up of a core of magnetic material around which is wound a coil of wire. An electromagnet only becomes magnetized when a current is passed through the coil. Electromagnet brushed DC motors use an electromagnet to generate their magnetic flux.

Electromagnet motors are divided into shunt motors, series motors, or separately excited motors depending upon how the rotor winding and field winding are connected together. In terms of motor output, these configurations are used in mid-range to heavy-duty motors.

Brushless DC (BLDC) motors

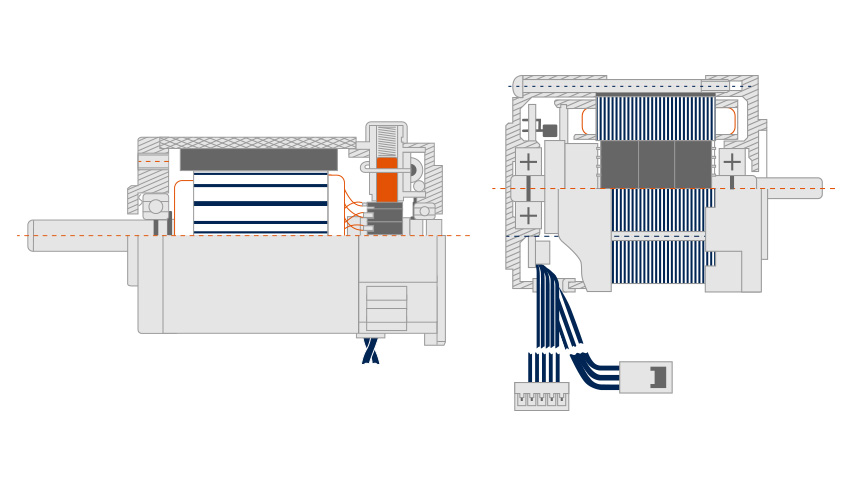

Brushless DC motors feature longer life and more efficient operation than their brushed counterparts. Brushless DC motors require a drive circuit (driver) that works by detecting the magnetic orientation of the rotor and supplying current to the winding accordingly. Because this drive circuit causes the motor to turn, brushless DC motors do not require a commutator and brushes.

This lack of a commutator and brushes avoids the need for maintenance and gives brushless motors a longer life. Recent years have seen the development of a wide variety of mechanisms that use brushless DC motors, especially in the automotive industry as well as in home appliances and precision machinery. Brushless DC motors that use permanent magnets in the rotor are called permanent magnet brushless DC motors (PM motors) or permanent-magnet synchronous motors.

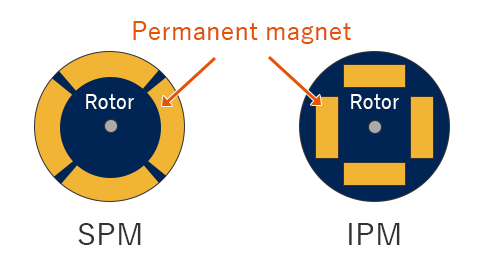

Brushless DC motors are used in a wide range of applications and can be divided into the following types based on how the permanent magnet is fitted into the rotor.

- SPM motors: The permanent magnets are attached to the side surface of the rotor.

- IPM motors: The permanent magnets are embedded in the interior of the rotor.

The embedded magnets of IPM motors make them mechanically safer than SPM motors and capable of faster speeds.

The two types of motors have the following characteristics.SPM: Surface permanent magnet

SPM motors have permanent magnets attached to the surface of the rotor.

IPM: Interior permanent magnet

IPM motors are a type of permanent-magnet synchronous motor (PMSM). They are rotating field motors that have permanent magnets embedded inside the rotor.

For example, IPM motors are used in hybrid and full electric vehicles. These high-performance motors are able to operate over a wide range of speeds, allowing them to match the high speed of a vehicle engine.

SPM and IPM for inner-rotor BLDC motor

SPM and IPM for inner-rotor BLDC motor

DC motors are found in a wide range of applications

DC motors are found in many different applications, not just in daily life, but also in offices and factories. Examples from the home include refrigerators and water heaters, also fans and other air conditioning systems.Commercial uses include copiers and printers as well as the ATMs operated by banks.

These are just some of the many areas of our daily lives in which DC motors are found, with other examples including vehicles, medical and measurement equipment, and residential building systems for things like ventilation.

List of the same series columns

- Applications for blower motor

- What is a blower motor?

- Advantages of brushless DC motors over brushed DC motors

- Features and applications of DC motors

- Is this brushless motor cheap or expensive? - What factors determine its price?

- What is a geared brushless DC motor?

- How does an electronic speed controller for a brushless DC motor work? And what should you consider when you choose the right one?

- Small brushless motors

- Difference between brushed motor and brushless motor

- What are the disadvantages of brushless DC motors? And how can they be overcome?

- Advantages of brushless DC motors: How they differ from brushed DC motors

- What is an actuator?

- How do brushless DC motors work? The need for a drive circuit explained

- Do brushless DC motors require a drive circuit? – Controlling brushless DC motors

- What is a brushless DC motor?

- How do brushed DC motors work? The need for regular maintenance explained

- Brushless DC motor applications: examples that demonstrate their features

- Stepper motor applications: Examples that demonstrate their features

- Motors designed for easy control: How do stepper motors work?

- What are the differences between brushed and brushless DC motors?

- What is a PSC motor

- What is a servo motor?

- What is a blower?

- What is a DC motor? - features and mechanisms

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others