Medical Device Innovation: The high pressure, fast response, quiet and compact blowers for CPAP and ventilators

-

Health & wellness

-

CPAP

-

Ventilator

ASPINA new blowers address the true needs of CPAP machine and ventilator manufacturers

“We are seeing a demand for high pressure and fast response blowers from medical device manufacturers globally.” Yutaka Nagai, General Manager of the Medical Engineering (ME) Business Unit of ASPINA, the group responsible for the design and manufacture of products for medical devices. These customer values of high pressure and fast response have been realized and incorporated in their newly developed blowers.

Blowers are widely used to generate inspiratory gas in ventilators and in Continuous Positive Airway Pressure (CPAP) machines for the treatment of Sleep Apnea Syndrome (SAS), where the flow rate is regulated by changing the rotation speed of the blower. We foresee that CPAP machines and ventilators will use longer and thinner tubing to make them easier to handle. In order for ventilators to supply a high flow rate while overcoming the pressure drop caused by long, thin tubing, blowers need to be able to generate high pressures. Simply increasing the size of the fan or motor would achieve this but would also increase the size and weight of the blower itself and therefore the overall size and weight of CPAP machines and ventilators. Having small, lightweight, and portable medical devices are a crucial advantage for improving patients’ quality of life especially in a homecare setting, where they may have limited space and limited ability to move heavy equipment on their own.

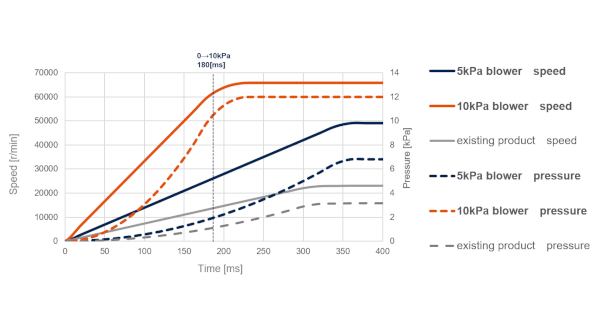

Additionally, various ventilation modes have been developed and put into practical use in recent years to assist ventilation and treatment of various diseases and conditions with the least possible burden on the patient. One example is a mode that detects spontaneous changes in the patient's breathing and adjusts air supply flow rate to compensate. Such changes require the blower to rise from 0 to 10 kPa in under 180 ms so that a large amount of air can be supplied promptly. For this reason, the inertia of the motor and fan must be low, and the motor must have sufficient power to accelerate the rotation of the fan instantly.

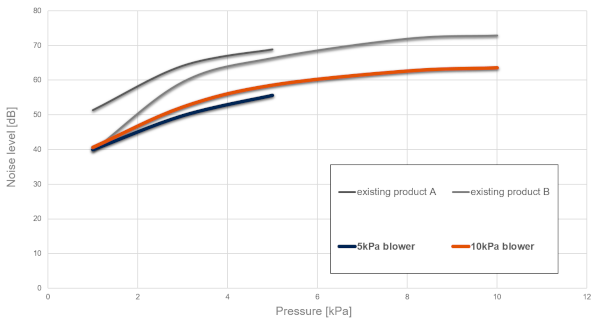

As a trusted supplier of blowers for use in CPAP machines for SAS treatment since 2011, we know that high noise level at certain frequencies called discrete frequency noise can be grating on patients and highly disruptive to their sleep cycles. We need to develop techniques to suppress the generation of such noise allowing us to engineer truly quiet blowers.

All things considered, a blower must be compact while being highly responsive and quiet. However, this would not be achievable if we only enlarge the diameter of the motor and fan to increase pressure and flow rate.

Made with 60 years of expertise in motor development and production, new design of motors and fans for blowers meet all conflicting requirements

We designed our blowers from the component level, - motors, impellers and housings. The ME Business Unit assembled a team of engineers specializing in motor and fan design, led by Takeki Sakai, Manager of Research & Development Section, and Chief Engineers Shin-ichiro Godo, Akishige Umematsu, and Naomasa Yoshida.

Godo, who oversees motor design, made the rotor small in diameter and robust enough to withstand the force of high speed rotation created by magnets with strong magnetic flux. He also designed a stator with low power loss by devising better winding methods. This enables high speed rotation and torque with low inertia at 50,000 rpm or more for a 5 kPa blower. In addition, he developed a new motor structure to transmit less vibration from the motor to the blower.

Umematsu, who oversees fan design, worked out the shape and structure of the scroll and impeller. In order to suppress discrete frequency noise, he determined the optimal number of impeller blades, shape of the impeller blades, and position of the impeller relative to the scroll. He designed the shape of the impeller by applying shaft thrust countermeasures to suppress aerodynamic and mechanical noise generated by other causes. He also minimized the impeller diameter to reduce the inertia of the impeller and keep the blower small.

The team was able to design our 5 kPa blower with a small housing - 62 mm in diameter and 50.3 mm in height.

In terms of performance, our new 5 kPa and 10 kPa blowers can continuously supply air at 100 and 200 liters per minute respectively, compared to our existing 2.2 kPa blower, which can only supply 40 liters per minute and has similar external dimensions.

In terms of responsiveness, our new 10 kPa blower met the market demand to rise from 0 to 10 kPa in under 180 ms, which was previously thought too difficult to achieve, by carefully designing the balance between the motor and fan.

Example of response time of ASPINA blowers. 180 ms rise time from 0 to 10 kPa achieved with 10 kPa blower under a test condition by ASPINA.

Example of response time of ASPINA blowers. 180 ms rise time from 0 to 10 kPa achieved with 10 kPa blower under a test condition by ASPINA.

In terms of quietness, both the 5 kPa blower and the 10 kPa blower succeeded in reducing noise at all pressures of typical ventilators. The noise level of the 5 kPa blower is more than 10 dBA lower than that of existing blowers tested in the same environment.

Noise level of ASPINA blowers. The 5 kPa blower is > 10 dBA lower than the existing blowers over the whole range of working pressure.

Noise level of ASPINA blowers. The 5 kPa blower is > 10 dBA lower than the existing blowers over the whole range of working pressure.

Every process from market research to production improves blower performance and quality

External view of 5 kPa blower. The performance has been greatly improved without changing the size from our existing model.

External view of 5 kPa blower. The performance has been greatly improved without changing the size from our existing model.

The ME Business Unit exhibited at trade shows in the U.S., Europe and Japan, where visitors were able to see prototype blowers and exchange ideas with us. We incorporated the feedback from the visitors into the blower design.

We produce major components we design, such as motors and impellers, and assemble them into blowers at our factory.

Aside from technology advancement and development we also focus on production innovation to achieve performance and ensure quality. For example, we perform subtractive balancing in the manufacturing process to correct imbalances in the rotor so that each blower does not generate out-of-tolerance noise.

Our factory in Japan is scheduled to obtain a certification of ISO 13485 medical devices quality management system for the production of blowers.

ASPINA is committed to enhancing patients’ QOL and reducing the burden on healthcare professionals through human centric medical device design and concept innovation

The new high pressure, fast response blowers are great choices for medical device manufacturers eager to develop industry-changing CPAP machines and ventilators.

ASPINA's blowers have been widely used not only in medical equipment but also in industrial equipment and home appliances. We have a large selection of small, high pressure, high flow rate, fast response time and quiet fan motors. Plus, we also develop compressors for medical devices and offer Original Design Manufacturer (ODM) contract development of medical devices.

We work with our partners throughout the product development journey--fostering science and over 60 years of motor design expertise to solve complex medical device challenges that will ultimately improve patient quality of life and ease the burden of healthcare workers. Please feel free to contact ASPINA.