Compact and high performance seat ventilation systems made possible with back outlet blower motor

-

Automotive

-

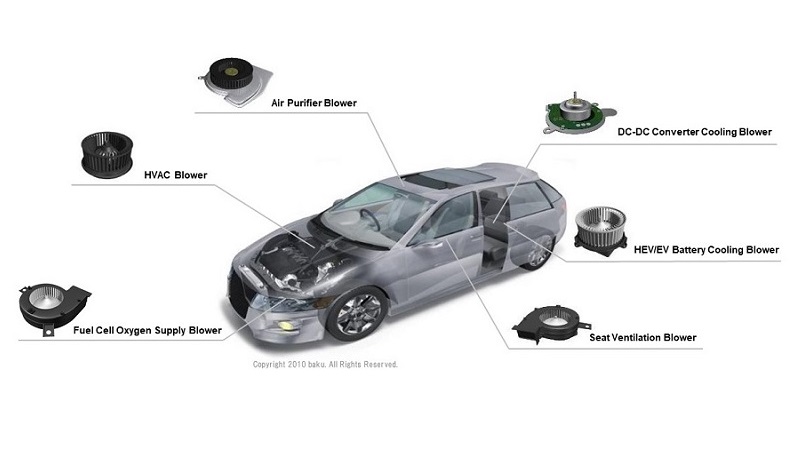

Automotive seat ventilation system

Automotive OEMs, seat and seat ventilation system manufacturers

The rise of EVs and added functions in car seats are shifting seat thermal comfort system trends, encouraging automotive OEMs and seat ventilation system manufacturers to deliver superior comfort

Comfort during driving is essential, and seat thermal comfort systems have become a common requirement for drivers. However, in recent years the growing EV prominence among drivers and the increasing functionality of car seats have had a significant impact on automotive OEMs, seat manufacturers (tier-1), and seat ventilation system manufacturers.

In EVs, the space available for seats is relatively smaller compared to traditional ICEs (Internal Combustion Engine vehicles). There’s also a growing demand for additional features such as massagers which have made the internal structure of seats more complex and further limiting the space available inside. These space constraints have challenged manufacturers to design and engineer automotive seat ventilation systems with compactness, while at the same time maintaining or improving performance to create the optimal seating experience.

Unique challenges surround seat ventilation system development and design

When considering how to make the seat ventilation system more compact, the selection of its major component, the blower motor, becomes highly important. However, there are several challenges that surround the development and design process of car seats and seat ventilation systems.

First, the process of designing the seats can only begin after the overall design of the entire vehicle has been decided and the interior design has been fixed. Therefore, specification review and supplier selection of seat ventilation blowers typically happen during the late stages of the vehicle development process. Furthermore, the seat design must cohere to the interior cabin design and not interfere with the intentions of the OEM interior designer.

Second, if there are changes to the cabin design, the seat design must also be changed immediately; and this is not uncommon. The problem, however, is that changing the seat design can often result in changes to the blower motor’s performance. For example, any changes to the seat material during the development stage could result in higher air resistance which can decrease the blower motor’s air flow.

As described above, automotive OEMs, tier-1 and seat ventilation system manufacturers must decide product specifications and design their products in a short period of time while also having the flexibility to accommodate sudden changes. Given these challenges which are unique to the automotive industry, selecting a blower motor that can withstand required specification changes without a complete redesign will remove a big burden from the development and design teams.

ASPINA’s high performance back outlet blower motor makes your seat ventilation systems compact - and a one-time selection

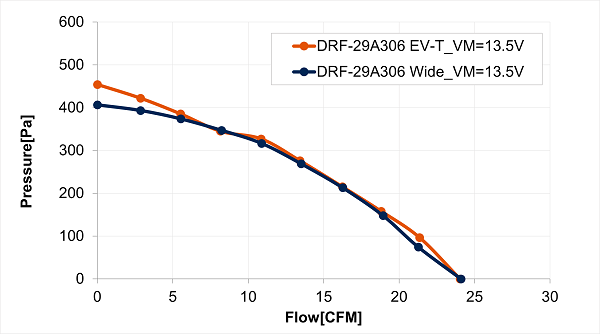

ASPINA’s DRF-29A306 EV-T back outlet blower motor maintains high performance while greatly reducing size. This blower motor achieves a maximum flow of 24 CFM and a maximum pressure of 450 Pa, despite its compact dimensions of 105 mm (approximately 4.13 inches) in length and width.

Generally, when blower motors are downsized, the flow rate/static pressure performance tend to decrease. However, our back outlet blower motor overcomes this through several innovative features.

ASPINA’s back outlet blower motor uses a turbo fan instead of a sirocco fan. This is because although the sirocco fan has high flow rate, it has poor efficiency. If you were to increase output of a sirocco fan blower motor with the same motor core, the current value would exceed its limit. Turbo fans on the other hand are more efficient but have a lower flow rate. To compensate this, our blower motor incorporates a back outlet structure; an original design by ASPINA. The back outlet structure enables increased flow rate with its increased outlet area. It also enables a compact size that cannot be achieved with a single or dual outlet structure. However, as increasing the outlet area causes a drop in pressure, a diffuser is attached. This slows down the air flow from the back outlet, which increases the blower motor’s static pressure.

When compared to our conventional single outlet blower motor DRF-29A306 wide (which is one of the mainstream blower motor structures), the back outlet blower motor DRF-29A306 EV-T achieves a downsize of 15mm in length and width while maintaining the same output. In other words, with ASPINA's back outlet blower motor, customers can maintain a high flow rate/static pressure performance while downsizing their products; features more than enough to withstand changes in required spec that accompany changes in seat design.

Performance curves of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

Performance curves of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

Size comparison of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

Size comparison of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

Top class quietness to further address seat ventilation system issues

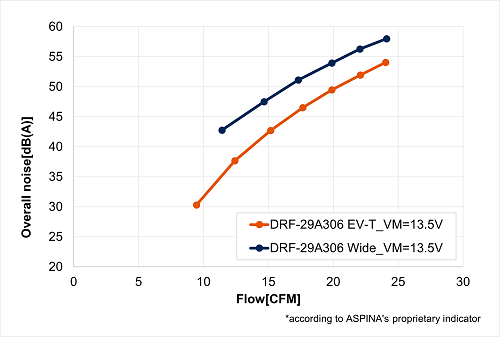

The back outlet structure not only allows for compact blower motor size while maintaining performance, but also reduces noise.

Noise reduction is an important consideration in EVs, as they tend to be quieter than ICEs. ASPINA’s back outlet blower motor can help reduce the noise levels inside of the vehicle and provide a quieter and more comfortable ride.

Noise generated by a blower motor is largely attributed to the sound of air being blown out of the outlet. The back outlet structure of ASPINA’s blower motor significantly reduces this with its increased outlet area. The low-frequency “rumbling” noise of ASPINA's back outlet blower motor is at a significantly lower level and is one of the quietest among blower motors of the same size available in the market.

Flow and overall noise curves of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

Flow and overall noise curves of back outlet blower motor DRF-29A306 EV-T and single outlet blower motor DRF-29A306 wide

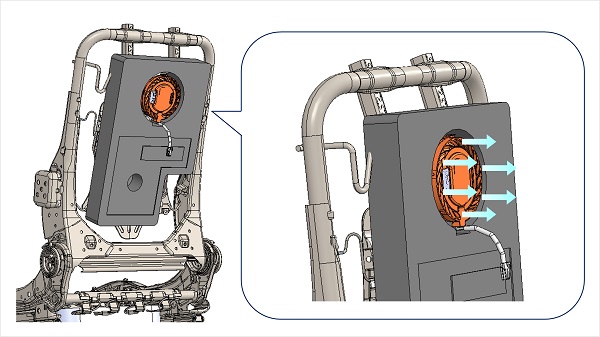

Another cause of noise related to the seat ventilation system is when the air blowing out of the blower motor interferes with surrounding structures. Mainstream single or dual outlet blower motors have their outlet on the side of the blower motor, which gives them not much choice but to exhaust air within the seat. This exhaust air blows directly on to surrounding structures and creates noise. A solution for this would be to secure free space around the outlet, but since the space within the seat is becoming smaller, engineers do not have this luxury. With ASPINA’s back outlet blower motor, manufacturers are freed from this problem because it can be installed so that the blower outlet faces out to the back of the seat and prevents air from flowing toward inner structures.

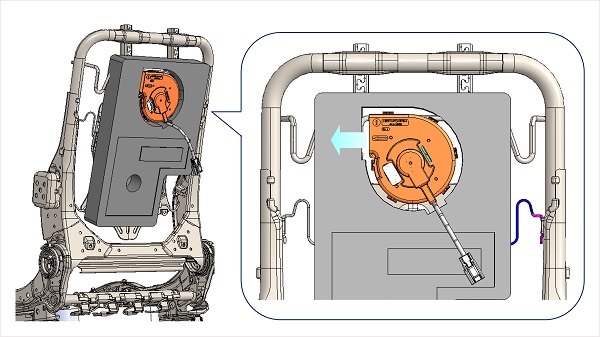

Installment and air flow image of back outlet blower motor DRF-29A306 EV-T

Installment and air flow image of back outlet blower motor DRF-29A306 EV-T

Installment and air flow image of a side outlet blower motor

Installment and air flow image of a side outlet blower motor

ASPINA has provided seat ventilation blowers to over 10 OEMs worldwide and has always worked closely with our customers to understand and meet the needs unique to engineers in this industry. Our seat ventilation blower motor is a product that caters to the concerns of seat and seat ventilation system engineers who frequently encounter design changes.

Related information

-

Seat ventilation blower

DRF-29A306 EV-TProducts & services

-

Casing structure innovation provides quiet and comfortable driving experience – Automotive seat ventilation blower motor

Technologies

-

Sleeve bearing development surpasses automotive industry standards – Automotive seat ventilation blower motor

Technologies

-

Accelerate product development: Rapid sampling and tailored solutions with ASPINA’s seat ventilation blowers

Case studies

Customer challenges

- Need to develop a seat ventilation system that can be installed in limited space, to address the shift of vehicle trends to EVs and increased functionality of seats.

- Seat ventilation blower motors must be downsized while maintaining high flow rate/static pressure performance.

- Need to accommodate frequent seat design changes.

ASPINA solutions

- The back outlet structure enables downsizing of the blower motor by 12.5% and can be installed in seats with limited space.

- By adopting a diffuser to the blower casing, a higher flow rate/static pressure performance than the mainstream side outlet blower is achieved. More than enough to accommodate frequent seat design changes.

- It supports a quiet and comfortable driving experience in EVs.

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others