Light and compact dialysis and infusion pumps made with ASPINA medical servo motor system

-

Health & wellness

-

Peristaltic pump

Dialysis machine, medical infusion pump

Changes in usage and application encourage development of new dialysis machines and medical infusion pumps

In recent years, there has been an increasing need for new dialysis machines and medical infusion pumps – more quiet, more compact, lighter weight, and lower power consumption.

The industry of dialysis machines and medical infusion pumps is expected to steadily grow worldwide. There are several reasons for this. In addition to the increasing social risk of disease, such as an aging population and changing lifestyles, the use environment is evolving to include more at-home use and use in isolated patient rooms to protect patients' quality of life (QOL) from the spread of infectious diseases. Another is that hospitals and facilities operating a large number of dialysis machines and infusion pumps are interested in replacing their current equipment with more portable ones that reduce and streamline the workload on healthcare professionals.

Peristaltic pump of dialysis machine

Peristaltic pump of dialysis machine

Infusion pumps are being used in a variety of new applications (e.g. new chemotherapy treatments), where there is also a need for high-resolution control of the infusion volume and portability to allow the patient to move around while undergoing treatment.

Motor selection is key in peristaltic pump design process

One of the most important keys to designing quiet, compact, lightweight, and power efficient dialysis machines and infusion pumps is the selection of the motor that drives the pump head with rollers or fingers to compress the tubing.

For example, a geared motor, which combines a motor and reduction gears to drive the pump head delivering blood or therapy solutions at low speeds, has several issues. For patients in a quiet room near the device, the noise produced from the friction and wind generated by the gears can disturb rest and sleep. In addition, the machine requires space to accommodate the gears. This can limit how compact the machine can be made.

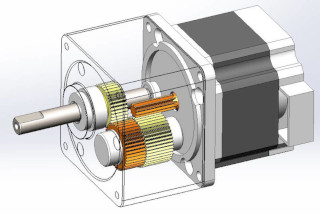

Gears housed in a geared brushless DC motor (example)

Gears housed in a geared brushless DC motor (example)

When developing battery-powered dialysis machines and infusion pumps, low power consumption is always a concern. Since the motor in the machine accounts for a large part of the power consumption of the entire machine, a motor should be selected that minimizes the power consumption.

Sometimes it is challenging for design teams developing a new dialysis machine or infusion pump to select the best motor. They do not have enough detailed information and knowledge about motor types, mechanisms, products, etc. Or perhaps, they do not have enough time to evaluate and select a suitable motor for the machine due to the limited development period and man-hours.

The direct drive motor can make a medical machine compact, low acoustic noise, low power consuming

ASPINA proposes servo motor system for medical applications to develop quiet, compact, and efficient dialysis machines and infusion pumps.

ASPINA servo motor system for medical applications

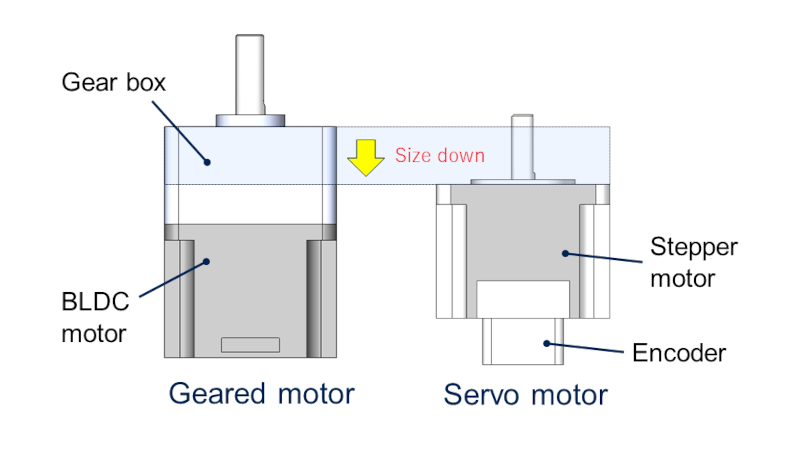

ASPINA servo motor system for medical applicationsASPINA’s servo motor system directly drives a stepper motor and produces high torque at low speeds without using gears. This makes the motor smaller and lighter than a geared motor. Its axial length is 75% of that of a conventional geared motor.

Size comparison between conventional geared motor and ASPINA servo motor system for medical applications

Size comparison between conventional geared motor and ASPINA servo motor system for medical applications

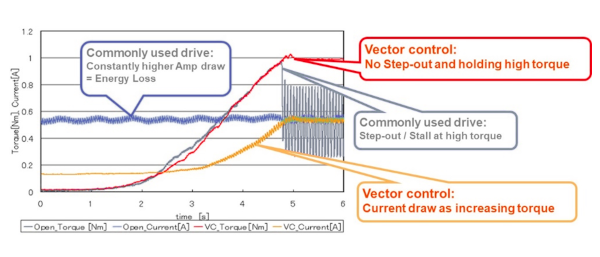

Besides achieving higher efficiency due to eliminating the need for a gearbox, we are also able to achieve higher efficiency by driving the stepper motor via vector control (FOC: field-oriented control). This allows the motor to generate higher torque without stalling and produces less unnecessary current dissipation because the current output is adjusted according to the required load level, unlike stepper motors driven via a regular drive controller.

Current consumption (orange) and torque (red) of ASPINA servo motor systems

Current consumption (orange) and torque (red) of ASPINA servo motor systems

The servo motor system generates less heat, contributing to flexible mechanical design for heat dissipation inside the machine. We have tested it with infusion pumps and the temperature rise was less than half that of conventional products for a given load level.

ASPINA, a world leader in hybrid stepper motors, apply stepper motors proven in medical devices to this servo motor system. We can also supply our products in conformity with the quality and safety standards of medical devices depending on customer needs.

A wide range of selection - motor size, integrated/separate driver, ODM/OEM as a module including roller/cam

Motor size (□28 - 60 mm) for ASPINA’s servo motor system for medical applications can be selected according to required flow rate. Both integrated and separate driver types are available, allowing customers flexibility when designing the housing of the machines.

ASPINA can develop and supply integrated modules that may include motor, rollers, and cams reducing time and cost for customers to develop and manufacture dialysis machines and infusion pumps.

As a partner in medical device development, ASPINA will help our customers grow their business.

Customer challenges

- Increasing need for at-home use and diversified applications demand quieter and smaller dialysis machines and infusion pumps.

- Limited knowledge of motors, which is the key to quietness and compactness, makes it difficult for manufacturers to select the right motor for new machines.

- Manufacturers need to reduce the development time and man-hours.

ASPINA solutions

- The direct drive stepper motor capable of low-speed rotation makes the machines smaller and lighter because it does not require gears.

- Smooth rotation, low power consumption and low heat generation by vector control (FOC)

- Motor size and driver integration/separation can be selected according to the flow rate and the housing requirements. ASPINA can develop and supply integrated modules with motor, rollers, and cams.

Contact us for more information

- New inquiry

- Prototype

- Upgrade

- Customization

- Your spec

- Literature

- Support

- Others